- Company

-

GEESYS

ESG

-

- Products

-

- Solar DCDB

- Solar Combiner Boxes

- Solar ACDB

- Solar AC Combiner Boxes

- Solar AC|DC DB

- Solar Reverse Panel

- Solar Junction Boxes

- Solar Dc String Combiner Boxes

- String Monitoring Box

- Weather Monitoring System

- Solar Pump Control Panel

- Solar Metering Panel

- Solar Charge Controller

- Solar Converters

- Solar PCU

- Solar Panel Structures

- Solar Array Junction Boxes

-

- Solutions

- Services

- Home

- Products

- Power Conditioning

- Inverter Transformers

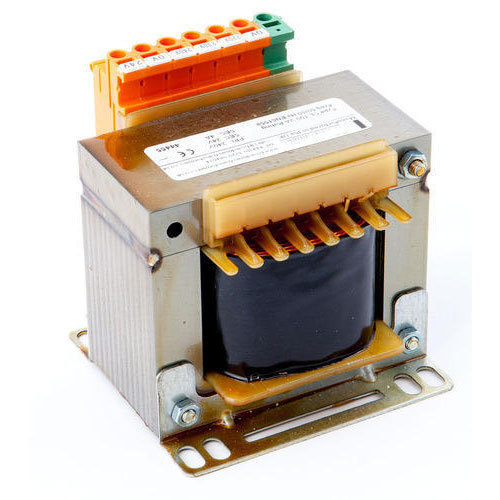

Inverter Transformers

With the help of our deft professionals and advanced infrastructure, integrated with latest equipment, we are engaged in manufacturing, exporting and supplying a wide variety of Electrical Transformer.Our skilled professionals utilize fine quality raw material, while manufacturing the entire range. Moreover, our offered range can be availed in a wide range of specifications, as per the requirements of our esteemed clients. Post manufacturing under our advanced infrastructure, a rigorous testing process is followed by our in-house experts to deliver a defect-free product at client's end.

GEESYS offer high quality High Current And High Voltage Transformer, Chokes, Inductors, Reactors, Step Up And Step Down Transformer and Single Phase & Three Phase Transformers. We are one of the leading manufacturer and supplier of these products. Our exclusive range of products include Electronic Transformers, Single Phase Isolation Transformer, Three Phase Isolation Transformer, Single Phase Transformers, Three Phase Transformers, Auto Transformer, H.T. Transformer With Built-in H.T. avr, Control Transformer, Power Chokes And Inductors. We manufacture these products in our well structured manufacturing units equipped with latest modern equipment and machineries like Lusona make Multi-spindle Automatic Coil Winding M/c and Automatic Engraving Machines.

Our products have features like Low Power Loss, Corrosion Resistant and Trouble Free Performance. We also have in our quality control department latest instruments like Digital Milli-ohm Meter and LCR Meters to check the quality of our products. We also use software like CAD and CAM to design our products as per the specifications provided by our customers. We attach importance to quality of our products. With our latest machineries and equipment we are in a position to offer our quality range of products to our customers and achieve their goodwill for our business.