Introduction

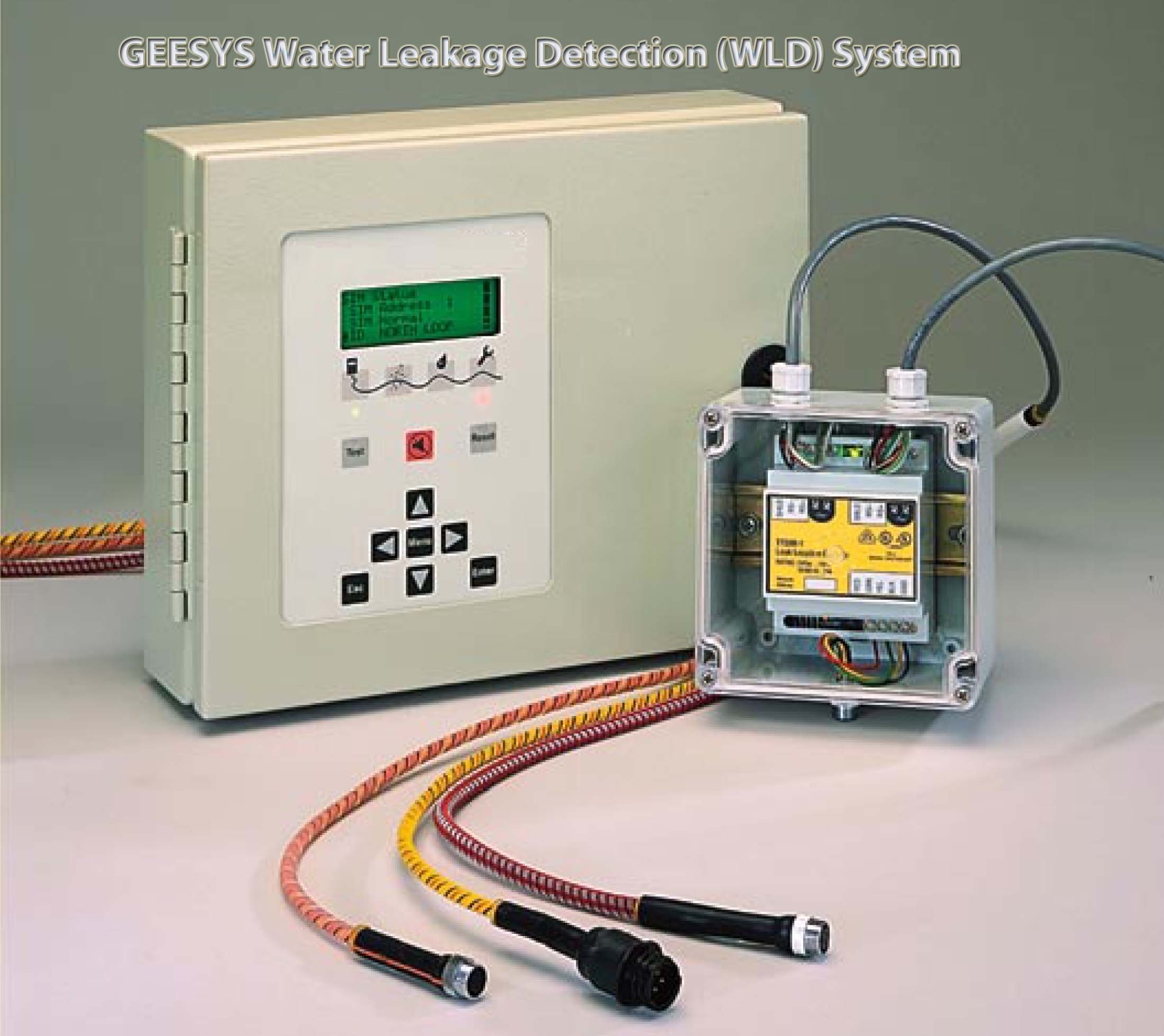

Water Leakage Detection System

The Water Leak Detection industry is small and specialized with only a few manufacturers operating world-wide. The original application was in the void created by "computer room" floors in the days of large main-frame computer systems. These use a modular, raised floor based around a structural "floor tile" usually 600mm square and supported at the corners by pedestals. The void created gave easy access and routing for the mass of power, networking and other interconnecting cables associated with larger computer systems - processors, drives, routers etc. mainframe computers also generated large amounts of heat so a void under the floor could also used as a plenum to distribute and diffuse chilled air around the computer room. The void therefore was like to have chilled water pipes running through it along with the drains for condensates associated with refrigeration plant.

In addition designers also found the floor void a very convenient place to route other wet services feeding bathrooms, radiators and other facilities.

Al leak occurring within a floor void would therefore go unnoticed until the hydrostatic head of pressure meant that the water found its way through to floors below where its dripping through the ceiling would be noted or, and more disconcerting, the water would penetrate the joints and connectors of the power or network cabling and cause system failure from short circuit

Technical Specifications

System Performance

General

The liquids leak detection system shall identify any abnormal presence of liquid on any point of its connected sense cables, to the nearest meter. In the event of leakage, an audible alarm is triggered, the indicator light changes to red and the display shows details of the fault, and its location to the nearest meter

Sense cable length

The system shall be capable of monitoring up to 1800 meter of cable from a single monitoring unit. This length shall not include the jumper cable.

Multiple leaks

The system shall be capable of managing information of all leaks related to the number of sense cables installed. (E.g. 120 sense cables installed=120 possible detected and displayed leaks).

Cable break fault

Besides leak, the system shall be capable to detect circuit interruption (cable break) on any of its connected sense cables. In the event of a "cable break", an audible alarm is triggered, the indicator light changes to red and the display shows "cable break" and its location.

Liquid types

The system shall be capable of detecting conductive and non-conductive liquids, as water, bases, acid, hydrocarbon and solvents using different types of sense cables. These sense cables shall be able to be connected simultaneously on one digital monitoring unit.

Security

To enter the configuration menu, the system shall require a password

Product Sense Cable Performance

The sense cable shall continuously perform three functions: to detect the presence of liquid at any point along its length, to detect a cut or break at any point along its length and to communicate digitally the nature and location of the fault to the nearest meter.

Construction

The sense cable shall consist of a helically-winded central core (data bus), on which PEHD (Polyethylene high-density) conductor wires are spiraled. This shall ensure a prompt detection as well as a short drying time after the risk is eliminated. The insulation and signal wires shall be of flame-retardant polymer. The jacket of sense wires shall be of conductive polymer on the ground wire. The active sense wire shall have special dust-proof construction and shall not be affected if in contact with any solid particles.

The sense cables shall be connected via the male and female connectors. A microcontroller shall be embedded in the sense cable to ensure digital and independent communication between each sense cable and the digital monitoring unit.